add on rfid tool tracking How to build an RFID tool tracking solution. An effective RFID tool tracking solution contains three core parts: the tags, a scanning solution or handheld reader, and asset tracking software to keep everything organized. Let’s take a look at each element in more detail below. The first thing you need to do is go to your settings app. Go to the tab that says “Control Centre.”. Then scroll down to “More Controls” and add the NFC tag reader to your phone’s control center. Now you need to open your .

0 · rfid tool tracking software

1 · rfid table tracker

2 · rfid position tracking

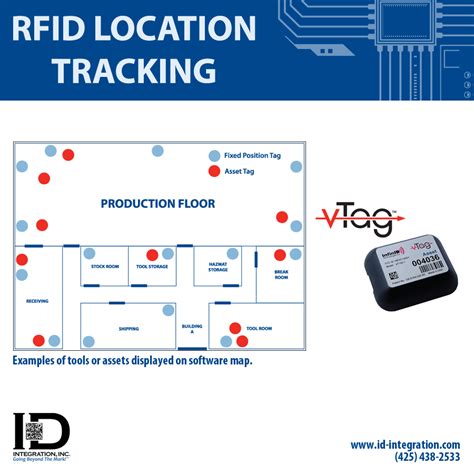

3 · rfid location tracking system

4 · rfid location tracking

5 · rfid inventory tracking

6 · rfid equipment tracking

7 · can rfid track location

Hold down the power button on your phone. Select the option to power off or restart your device. Wait for your phone to completely shut down. After a few seconds, press the power button again to turn your phone back on. .

How to build an RFID tool tracking solution. An effective RFID tool tracking solution contains three core parts: the tags, a scanning solution or handheld reader, and asset tracking software to keep everything organized. Let’s take a look at each element in more detail below.

RFID Track and trace complete tool inventory across multiple locations in real time. Rugged RFID tags can be accurately scanned without direct line of sight, even when dirty or greasy. .RFID tool tracking systems can manage tools, including preventive maintenance, of all sizes, shapes, and materials – from small, metal surgical tools to large, metal and plastic power . How to build an RFID tool tracking solution. An effective RFID tool tracking solution contains three core parts: the tags, a scanning solution or handheld reader, and asset tracking software to keep everything organized. Let’s take a look at each element in more detail below.RFID Track and trace complete tool inventory across multiple locations in real time. Rugged RFID tags can be accurately scanned without direct line of sight, even when dirty or greasy. Automated self-service tool check-in/check-out after hours and .

RFID tool tracking systems can manage tools, including preventive maintenance, of all sizes, shapes, and materials – from small, metal surgical tools to large, metal and plastic power drills. Tool Tracking Examples DeWALT understands the value of their own tools and not only do they offer add-on connected tool trackers, similar to Tile, but they also have an entire lineup of connected tools and attachments to add connectivity to existing tools. The DeWALT Tool Connect Tag (seen above) can be glued, riveted or screwed directly to equipment.

Simply mount the mini IoT tags to your power tools or portable equipment and view it’s last location on your mobile or on the cloud. The tags are easy to mount yourself, so you can instantly start tracking your tools without having to organize appointments with engineers.The GigaTrak RFID Tool Tracking System helps organizations improve the visibility of their fixed assets by enabling them to automate physical asset inventories. Track the movement of assets, monitor assets in real-time for security and safekeeping.

Efficiently keep track of you tools and equipment with ToolWorks RFID Asset Tracking software. With in-built support for reading RFID tags using Smartphones, ToolWorks provides a flexible solution to track your assets on the go, wherever they are!

Track and manage products through Site Manager with the TOOL CONNECT ™ Chip, a subtle add-on that provides instant system connectivity to TOOL CONNECT ™ Chip-Ready tools. The cost of an RFID system depends on several things. These include the size of your facility and the complexity of the setup. The type of hardware and software needed also plays a role.On average, a basic RFID system costs between ,000 to 0,000. More advanced systems can cost from 0,000 to 0,000 or more. Radio frequency identification (RFID) technology is well equipped for tracking tools on a worksite, whether that involves wrenches on a manufacturing site or generators in a large utility yard. However, ensuring the technology provides a solution that works requires some planning. Tool-tracking systems are not “one size fits all” propositions.

How to build an RFID tool tracking solution. An effective RFID tool tracking solution contains three core parts: the tags, a scanning solution or handheld reader, and asset tracking software to keep everything organized. Let’s take a look at each element in more detail below.RFID Track and trace complete tool inventory across multiple locations in real time. Rugged RFID tags can be accurately scanned without direct line of sight, even when dirty or greasy. Automated self-service tool check-in/check-out after hours and .RFID tool tracking systems can manage tools, including preventive maintenance, of all sizes, shapes, and materials – from small, metal surgical tools to large, metal and plastic power drills. Tool Tracking Examples DeWALT understands the value of their own tools and not only do they offer add-on connected tool trackers, similar to Tile, but they also have an entire lineup of connected tools and attachments to add connectivity to existing tools. The DeWALT Tool Connect Tag (seen above) can be glued, riveted or screwed directly to equipment.

Simply mount the mini IoT tags to your power tools or portable equipment and view it’s last location on your mobile or on the cloud. The tags are easy to mount yourself, so you can instantly start tracking your tools without having to organize appointments with engineers.The GigaTrak RFID Tool Tracking System helps organizations improve the visibility of their fixed assets by enabling them to automate physical asset inventories. Track the movement of assets, monitor assets in real-time for security and safekeeping.Efficiently keep track of you tools and equipment with ToolWorks RFID Asset Tracking software. With in-built support for reading RFID tags using Smartphones, ToolWorks provides a flexible solution to track your assets on the go, wherever they are!Track and manage products through Site Manager with the TOOL CONNECT ™ Chip, a subtle add-on that provides instant system connectivity to TOOL CONNECT ™ Chip-Ready tools.

The cost of an RFID system depends on several things. These include the size of your facility and the complexity of the setup. The type of hardware and software needed also plays a role.On average, a basic RFID system costs between ,000 to 0,000. More advanced systems can cost from 0,000 to 0,000 or more.

rfid tool tracking software

contactless smart card data storage

Highlighting the new affiliates this season is the addition of WINGS 94.3 as Auburn .

add on rfid tool tracking|rfid table tracker